H A N D L I N G

How to best use our print media

Thank you very much for choosing our products! The versatile print media of the mediaJET® series have been created and carefully assembled especially to meet the demands and requirements of photographers and artists. Whether it‘s the classic portrait print, special prints on effective surfaces or the reproduction of works of art: Our unique print media always provide the perfect basis for long-lasting photo and fine art prints and contemporary presentations of the highest quality.

In order to guarantee optimal results and maximum durability when using mediaJET® print media, please observe the following instructions for use.

For customer service, advice, questions & suggestions, you can reach us by telephone +49 (74 24) 94 85-0 or by e-mail service@mediajet.de.

Storage

- Our Photo and FineArt media are best stored in their original packaging, at a temperature of 15–25°C in a dark environment and with a relative humidity between 45 and 60 %. Do not store in rooms with possible pollutant concentrations or in which solvent-containing lacquers, paints, varnishes or similar are processed. This can lead to paper and coating discolouration.

- Do not use any films or adhesives with plasticizers and/or solvents for further processing or packaging of the prints, but only PA/PE composite films and labels with water-based adhesive. This prevents the paper from discolouring through the packaging.

Pressure

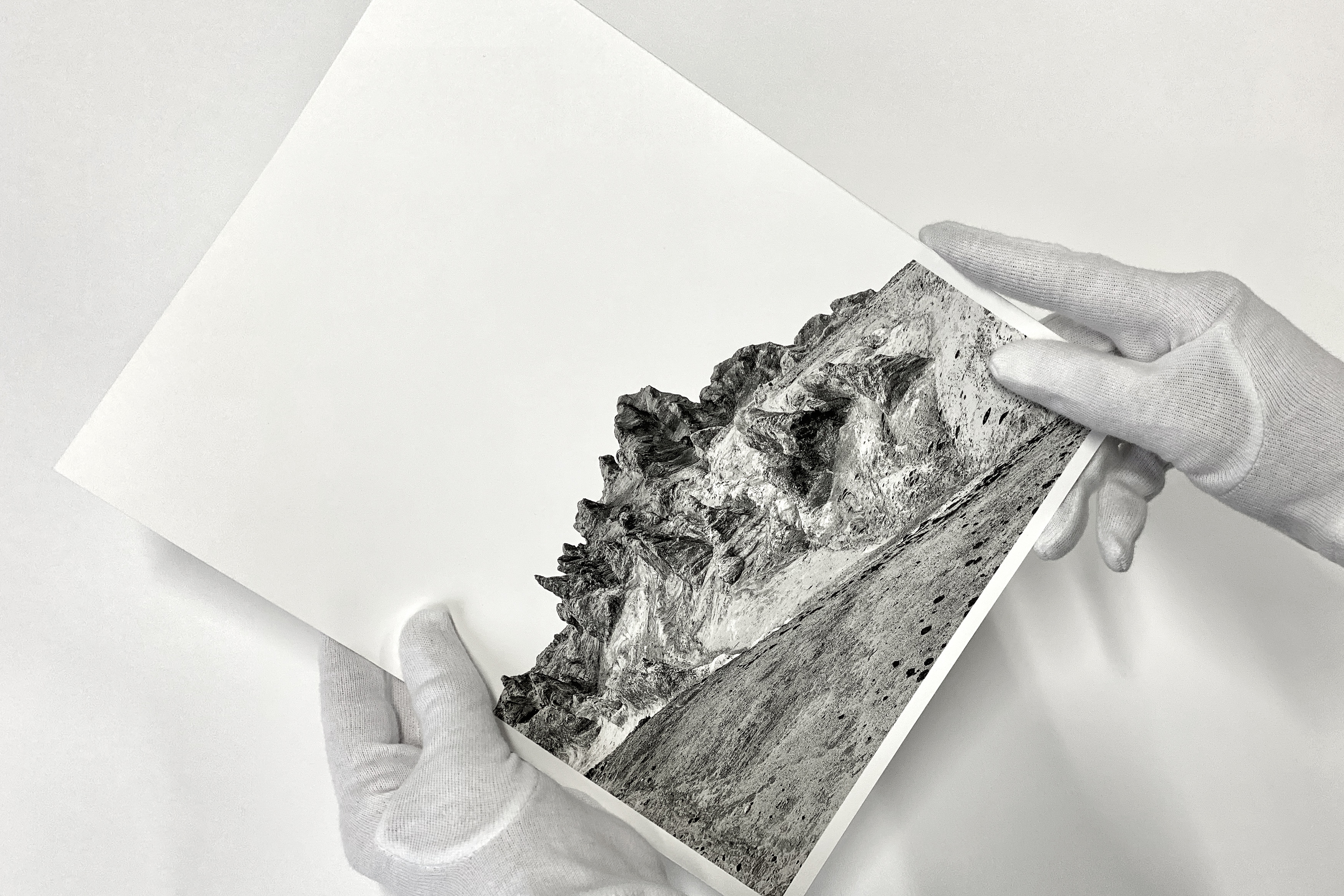

- A 24-hour climate adjustment in the processing room is recommended. By wearing cotton gloves you avoid fingerprints, as moisture and skin oils can impair the quality of the print.

- Only the coated side of the FineArt paper is intended for printing. The printing side is always on top of format goods and on the outside of rolls.

- When printing our Photo and FineArt media, we recommend using the device-specific sheet feeder, where the paper ideally runs flat through the printer. Pay attention to the recommendation of your printer manufacturer and avoid creases, folds and rolling of the paper. These can lead to problems when printing.

- For best results, use water-based dye/pigment inks. The use of pigment inks ensures that ink-jet prints are more resistant to light. After printing, these papers should not be exposed to direct sunlight or increased humidity and high temperatures in order not to negatively influence the image and colour properties.

- We recommend calibrating the papers beforehand on the printers to be used and the appropriate inks. The best printing results can be achieved with the correct printer driver settings and the use of media-specific ICC profiles, which we make available to you online for a wide variety of printers. Without professional colour management and calibration, the colour impression (colour rendering) can deviate significantly.

- The optimal conditions for processing mediaJET® papers are given at 20–30°C and 30–55% relative humidity. After printing and before further processing, allow the paper to dry sufficiently. Ideally, the paper should be dried for 24 hours or at least overnight.

- Our media are intended exclusively for printing with an ink-jet printer using the original inks of the manufacturer. Other printers, for example laser printers, can be damaged and are not suitable for the use of our media.

- Printing several sheets of paper with a natural surface one after the other can lead to fine abrasion, which can worsen the transport in the printer. In this case, simply run a few sheets of uncoated standard paper through the printer to absorb the abrasive dust.

- Our protective spray for FineArt papers with a natural matt surface increases UV stability and protects high-quality prints against negative environmental influences, fingerprints and moisture.

- When laminating our papers, use only adhesives that are free from silicone and solvents to prevent discolouration and yellowing.